Water Treatment & Reverse Osmosis Membranes

The use of reverse osmosis membranes in the water treatment industry is standardized practice, due to the requirement of filtration to take place in removing unwanted impurities from water. Membrane water treatment is done through the use of barriers that allow only specific substances to pass through the small pores of the membrane while not allowing other types of contaminants. There are a variety of membranes in use throughout the market which act as processes in treating groundwater, surface water, and wastewater to a level that is acceptable for industries and especially consumption. It is a rapidly growing industry, as a result of the need to combat low quality water sources such as rivers, lakes, wells, streams, and the ocean, in order to provide more alternative methods in supplying healthy, safe, steady, and accessible water to the masses.

As per mentioned, there are different types of membranes which can be utilized for water treatment. The factors that necessitate which membrane would be more effective relies upon the types of contaminants existing in the water, and the desired water quality by the user.

Category: Key Components of Water Treatment Plants

You May Also Like

Cartridge filters are easily produced modular filters that are placed into housings and work in eliminating particles, or in lesser instances chemicals from water.

The use of reverse osmosis membranes in the water treatment industry is standardized practice, due to the requirement of filtration to take place in removing unwanted impurities from water.

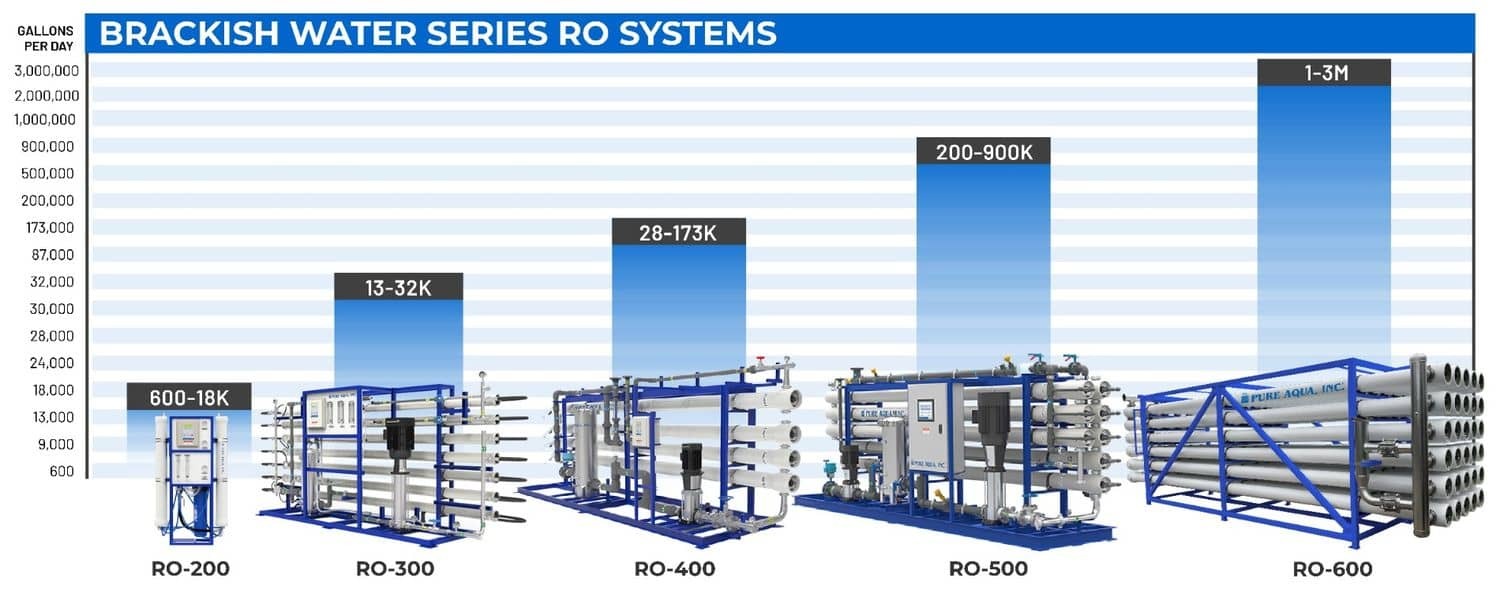

first-rate brackish water treatment solutions in a variety of industrial/commercial applications and industries. Our water purification company delivers brackish water reverse osmosis systems

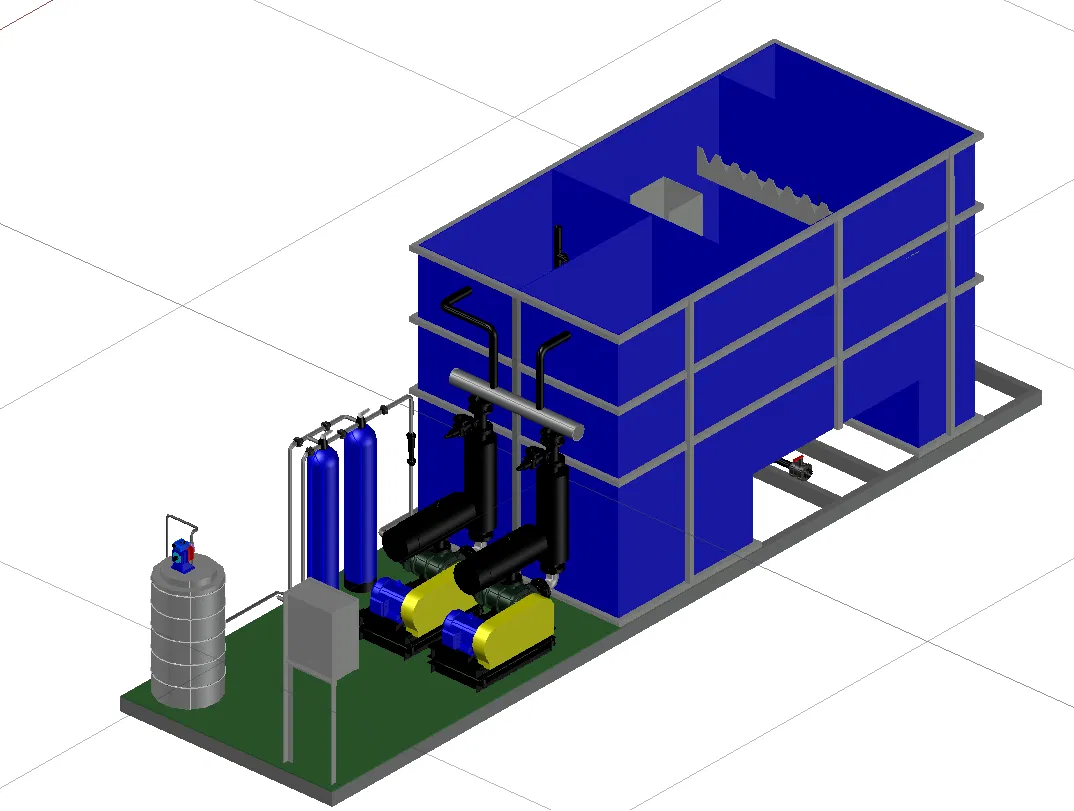

We offer professional 3D design, modeling, and drafting services for all types of water, desalination, and wastewater treatment plants, ensuring accurate, optimized,

deliver safe, high-quality drinking water by effectively removing suspended solids, pathogens, dissolved salts, and other harmful contaminants. T

modular water storage tanks provide durable, corrosion-resistant solutions for storing raw or treated water in desalination and water treatment plants.from 500 L to 500,000 L

Chemical Wastewater Treatment Plants are specifically designed to manage and provide and treat wastewater generated from chemical manufacturing and processing industries

industrial Wastewater Treatment Plants using Dissolved Air Flotation (DAF) efficiently remove oils, greases, and suspended solids from industrial effluents. Designed for various industries, these plants ensure compliance with environmental regulations

Our stainless steel desalination plants provide reliable, high-quality freshwater for industrial applications. With capacities from 3 to 1000 m³/day, they offer modular, corrosion-resistant solutions for diverse industrial water needs. Energy-efficient

desalination systems feature a wide range of capacities and modular designs, offering flexible and efficient solutions tailored to diverse water sources and project requirements.